3D Printing test

Category

ProjectsAbout This Project

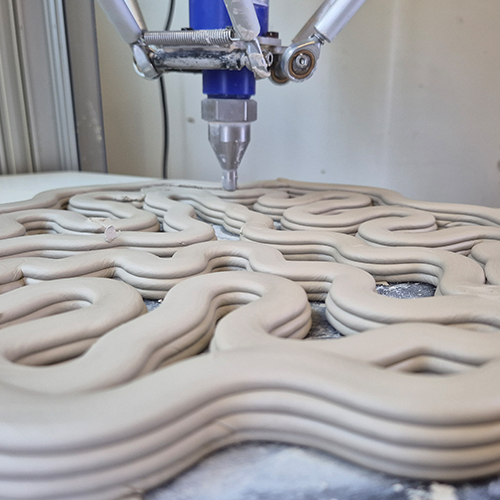

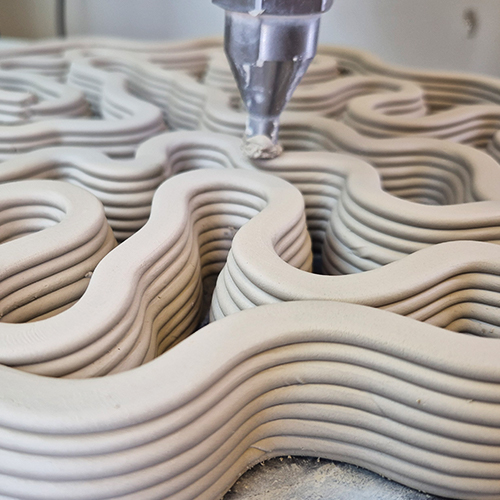

The initial 3D extrusion printing trials aimed to validate the shape, consistency of the mortar, and material strength. The first test using this method was carried out with ceramic mortar due to its easier printability and good filament resolution in this early experimental phase, prior to printing with the developed mortar.

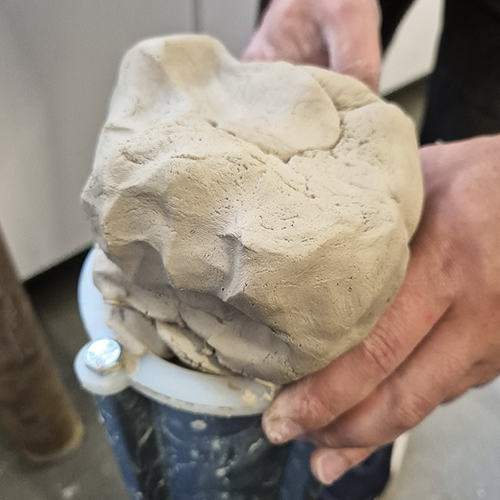

The ceramic mortar must be mixed with the correct water ratio to achieve malleability and allow proper filament extrusion. One of the main challenges in this process was determining the right water-to-mortar ratio. If this proportion is not accurately set, it can cause the extruder nozzle to clog, requiring the material to be removed and the process restarted.